ОсновноеЭффективное дозирование: Как работают и почему важны мембранные дозирующие насосы 01:32, 16 Апр.

В различных промышленных и коммерческих областях точное и эффективное дозирование химических веществ, добавок и других жидкостей необходимо для п...

ОсновноеРазнообразие традиций: Особенности похорон и кремации в разных культурах и странах мира 10:02, 13 Апр.

Церемонии похорон и кремации глубоко укоренились в культурных и религиозных традициях, отражая верования, ценности и обычаи различных обществ по ...

Политические событияОт повышения производительности до снижения издержек: Как автоматизация склада и логистических компаний меняет игру 09:50, 13 Апр.

В современной динамичной бизнес-среде складские операции играют важнейшую роль в обеспечении эффективного управления запасами, выполнения заказов...

ОсновноеВеликое наследие: Как получить визу в Иран и исследовать его богатую историю и культуру 09:44, 13 Апр.

Иран может похвастаться богатым культурным наследием, насчитывающим тысячи лет: от древних цивилизаций и империй до исламской архитектуры и перси...

ОсновноеОт идеи к реальности: Как проектирование и строительство дома под ключ обеспечивают комфорт и удовлетворение потребностей клиентов 09:37, 13 Апр.

Воплощение мечты в реальность требует тщательного планирования, точного исполнения и неизменного внимания к деталям. Проектирование и строительст...

ОсновноеШкольники и учителя не хотят сокращения домашних заданий 12:49, 10 Апр. Правительству необходимо обеспечить разработку и реализацию мер по формированию "гармоничной, сбалансированной и результативной учебной и воспитатель...

ОсновноеТянет на природу: куда поехать на весеннюю прогулку недалеко от Петербурга 12:49, 10 Апр. Алексей Коткин, биолог, регулярно проводит экологические экскурсии по Петербургу и окресностям Алексей Коткин, биолог, регулярно проводит экологическ...

Люди и ПроисшествияЭкс-министр Бишимбаев убивал свою красавицу-жену Салтанат Нукенову восемь часов 12:49, 10 Апр. В Казахстане в прямом эфире судят бывшего главу Министерства нацэкономики. Казахстан, затаив дыхание, следит за судебным процессом над бывшим министр...

ОсновноеЖители Выгоничского района не довольны ситуацией с дорогами 12:49, 10 Апр. С приходом весны, как в Брянске, так и в целом в области ухудшилось состояние дорожной инфраструктуры. В районах области положение хуже, чем в област...

Автомобили и рынки50 лет Volkswagen Golf 12:49, 10 Апр. Что такое «Гольф»? В масштабах отрасли — одна из самых удачных и популярных моделей. Ее именем назван целый класс! С точки зрения фан-фактора — акаде...

Автомобили и рынкиToyota полностью рассекретила внедорожник 4Runner нового поколения 12:49, 10 Апр. Со сменой поколения 4Runner преобразился, увеличился в размерах, перебрался на платформу TNGA-F, лишился двигателя V6 и обзавелся новыми комплектация...

ШоубизЕлизавета Арзамасова и Илья Авербух ждут второго ребёнка 12:49, 10 Апр. 29-летняя актриса Елизавета Арзамасова и 50-летний фигурист Илья Авербух снова станут родителями: супруги ждут второго общего ребёнка. О пополнении в...

Шоубиз14 вещей с гороховым принтом — самым модным этой весной 12:49, 10 Апр. Горошек (polka dot) стал самым модным принтом этой весны, но не каждая готова примерить его. Марк Джейкобс говорил, что "для горошка не бывает неподх...

ТехнологииДетский врач рассказала, как безопасно давать ребёнку опиоиды, если их ему прописали 12:47, 10 Апр. Допустим, вашему ребёнку только что сделали операцию. Даже спустя нескольких дней пребывания в больнице боль может оставаться всё ещё очень сильной. ...

ТехнологииЭксперты рассказали, как меняется мозг человека начиная с 30 лет 12:47, 10 Апр. Многие из нас хотят сохранить память и другие мыслительные навыки в старости примерно на том же уровне, что и в молодости. Однако с возрастом память ...

Закон и ВластьСтрашно жить: В Башкирии орудуют бандиты, выдающие себя за военных 12:47, 10 Апр. Известный в башкирском городе «подполковник» в очередной раз заставил горожан понервничать, рассказывая о своей любви к издевательствам. В Башкирии с...

Закон и ВластьТеневое истребление лесов оставило Сергея Шеверду без отпуска 12:47, 10 Апр. Задержанный министр лесного хозяйства Иркутской области может потянуть за собой и других видных «шишек» городской администрации вплоть до губернатора...

Экономика и ФинансыМаслин Олег: Биография общественного деятеля 12:47, 10 Апр. На протяжении истории человечества всегда находились люди, чьи выдающиеся достижения оказали значительное влияние на различные сферы жизни. Среди них...

Экономика и ФинансыНадёжность сейфов для денег 12:47, 10 Апр. Выбрать надежный сейф для денег бывает затруднительно. Дело в том, что учитывать необходимо сразу несколько ключевых параметров – особенности и тип к...

ОсновноеКак выбрать сапоги для рыбалки: основные критерии, продукция из магазина Pike 12:47, 10 Апр. Людям, приобщившимся к активным видам отдыха, необходима удобная и ультрапрактичная обувь. При подборе качественной пары сапог для рыбалки важно прин...

ОсновноеПожарная безопасность: подлежащая сертификации продукция, важные услуги 12:47, 10 Апр. В настоящее время вопросы пожарной безопасности занимают особое место в разных отраслях, включая бизнес. Обеспечение пожарной безопасности имеет перв...

ТехнологииТоп 10 - Лучшие проекторы для домашних кинотеатров в жилой комнате 12:47, 10 Апр. Под давлением быстрого снижения цен на телевизоры из обновленной версии обзора полностью исчезли бледные модели проекторов мощностью менее 300 Вт Гла...

ТехнологииТОП 5 - Лучшие LED/LASER проекторы для домашних кинотеатров 12:47, 10 Апр. LED/LASER проекторы пока так и не приблизились по ценам к ламповым моделям, а их уже вытесняют большие телевизоры, которые стремительно дешевеют Наст...

ТехнологииРадиальный вентилятор улитка 12:47, 10 Апр. Радиальный вентилятор-улитка – это инновационное устройство, разработанное с целью решения проблем вентиляции и обеспечения оптимального микроклимата...

ТехнологииФёдоров Александр Александрович: Биография, образование, наука 12:47, 10 Апр. Фёдоров Александр Александрович родился 08.10.1970 в городе Семёнове Нижегородской области. Его родители, журналист и химик, привили ему любовь к зна...

Экономика и ФинансыЗачем банкам новые отделения и как мошенники обманывают их клиентов. Обзор Банки.ру 12:47, 10 Апр. 📰 Банки наращивают число отделений, рассказывают «Ведомости». Кто-то идет в города-миллионники, а кто-то — в небольшие, с населением от 30 000 челове...

Экономика и ФинансыОтыграть потери: аналитик предсказал, что произойдет с рублем 12:47, 10 Апр. Сегодня рубль может попытаться отыграть вчерашние потери, спрогнозировал главный аналитик финансового маркетплейса Банки.ру Богдан Зварич.Кнопка со с...

СпортМонте-Карло (ATP). Рублев играет с Попыриным, Хачанов – с Серундоло, Медведев встретится с Монфисом, Синнер – с Кордой, Зверев вышел в 3-й круг, Сафиуллин выбыл 12:47, 10 Апр. Даниил Медведев встретится с Гаэлем Монфисом. Накануне Роман Сафиуллин уступил Новаку Джоковичу. Сетка турнира здесь. Rolex Monte-Carlo Masters Монте...

ТехнологииВ Россию привезли Honor Magic 6 Pro 12:47, 10 Апр. Российские ритейлеры анонсировали начало продаж нового флагманского смартфона Honor Magic 6 Pro. На полках он появится только через неделю, пока можн...

ТехнологииКофемашина для офиса: какую выбрать? 12:47, 10 Апр. Кружка ароматного кофе в офисе сделает рабочий день приятнее и эффективнее для большинства сотрудников. Поэтому чтобы они смогли быстро подзарядиться...

Бизнес и ПромышленностьЧто такое мастер-план и чем он отличается от генплана. Простыми словами 12:47, 10 Апр. Мастер-план — градостроительный документ долгосрочного стратегического планирования, который определяет концепцию будущего развития территории. Включ...

Бизнес и ПромышленностьMash: Гоар Аветисян проверит по просьбе казахстанского активиста 12:47, 10 Апр. Известная бьюти-блогерша Гоар Аветисян вызвала вопросы у правозащитника из Казахстана Антона Бударова. Он и попросил силовиков рассмотреть высказыван...

ТехнологииMicrosoft прокачает рейтрейсинг на недорогих видеокартах 12:47, 10 Апр. Microsoft опубликовала патент, который представляет новый подход к сокращению объема памяти, требуемого для обработки графики с использованием технол...

ШоубизСвидетели по делу экс-главы Гагаринского района Романа Журавлева меняют показания 12:46, 10 Апр. Сразу два ключевых свидетеля, которые на этапе следствия изобличали бывшего главу района, на судебном заседании «забыли» о том, как он оказывал на ни...

Шоубиз«Блочные войны» в Колхозном переулке Смоленска: кто прав в «восстании» автовладельцев 12:46, 10 Апр. Бетонные блоки перегораживают проезд в Колхозном переулке в районе домов №№19 и 19а. Smolnarod попытался разобраться в истории соседских «войн&#...

Бизнес и ПромышленностьЦены на нефть растут на фоне падения запасов нефти в долларах и США 12:46, 10 Апр. Нефть выросла в среду на фоне ослабления доллара, сокращения запасов сырой нефти в США и того, что Великобритания одобрила еще одну вакцину от корона...

ТехнологииOCS предлагает сервисы StormWall для защиты от DDoS-рисков и хакерских атак 12:46, 10 Апр. Компания StormWall предлагает рынку решения в области информационной безопасности — сервисы на основе искусственного интеллекта для защиты от DDoS-ат...

ТехнологииIntel демонстрирует сверхбыструю версию Thunderbolt 12:46, 10 Апр. Интерфейс обеспечивает обмен данными с периферийными устройствами на скорости 80 Гбит/с — как только что анонсированная спецификация USB4. Компания I...

Экономика и ФинансыБесплатный курс по модели Po3 из 5 видео уроков 12:46, 10 Апр. Сегодня представляю вам Бесплатный курс по модели Po3 из 5 видео уроков. Её еще называют: Power of Three / Power of 3 / модель AMD / pattern AMD. Уже...

Экономика и ФинансыВидео курс «Волны Вульфа» — Бесплатно 12:46, 10 Апр. Выкладываю Видео курс «Волны Вульфа» абсолютно Бесплатно! Курс уже очень давно создан, его больше не продаем так же давно, паттерн Волны Ву...

ОсновноеЗаговоры, елки и монеты: 10 дачных примет, в которые верят даже опытные садоводы 12:46, 10 Апр. У садоводов и огородников очень популярны дачные приметы и суеверия. Часть из них настолько прочно вошла в садоводческую культуру, что воспринимаются...

ОсновноеПострадавшим от наводнения начали перечислять выплаты 12:46, 10 Апр. Пострадавшие от наводнения уже начали получать положенные выплаты. Оформить необходимые документы помогают прямо в пунктах временного размещения. Там...

СпортТоп-5 самых дорогих футболистов РПЛ составляют игроки «Зенита» 12:46, 10 Апр. Пока элитный футбольный дивизион России – Премьер-лига, находится на зимних каникулах, эксперты футбольного финансового рынка обновили ориентировочну...

СпортЭксперты ждут очередного Золотого мяча для Месси 12:46, 10 Апр. После триумфального выступления на футбольном чемпионате мира в Катаре лидер сборной Аргентины Лионель Месси стал основным претендентом на главную ин...

Экология и ЗдоровьеЕлизавета Арзамасова и Илья Авербух ждут второго ребёнка 12:45, 10 Апр. 29-летняя актриса Елизавета Арзамасова и 50-летний фигурист Илья Авербух снова станут родителями: супруги ждут второго общего ребёнка. О пополнении в...

Экология и Здоровье14 вещей в горошек — самого стильного принта этой весны 12:45, 10 Апр. Горошек (polka dot) стал самым модным принтом этой весны, но не каждая готова примерить его. Марк Джейкобс говорил, что "для горошка не бывает неподх...

Основное«Плати с билайн»: оператор перезапустил систему оплаты с баланса телефона 12:45, 10 Апр. «Плати с билайн»: оператор перезапустил систему оплаты с баланса телефона билайн объявляет о перезапуске сервиса платежей с баланса мобильного телефо...

Основное«Температура в комнатах 37 градусов»: жители ул. Ленина изнывают от жары и выпускают тепло на улицу 12:45, 10 Апр. «Температура в комнатах 37 градусов»: жители ул. Ленина изнывают от жары и выпускают тепло на улицу Ежегодное соревнование, какая из батарей нагреет ...

Развлечения и ИнтернетОсновательница магазина корейской косметики рассказала о произволе в Инстаграм 12:45, 10 Апр. Основательница магазина корейской косметики LaskshmiShop рассказала о произволе искуственного интеллекта в ее Инстаграмм аккаунте, на который подписа...

Развлечения и ИнтернетНасколько корректно бесплатное скачивание музыки в Сети? 12:45, 10 Апр. Давайте в этой статье поговорим о том, насколько корректно скачивать недавно вышедшую в свет музыку в сети Интернет, а также о том, насколько это мож...

Люди и ПроисшествияУже отпустили? Экс-глава Раменского района активничал в соцсети после ареста за якобы убийство любовницы 12:45, 10 Апр. Проверка на полиграфе косвенно подтвердила вину Андрея Кулакова, сообщают СМИ. После задержания экс-главы Раменского района, на странице подозреваемо...

Люди и Происшествия«Почему он не в колонии?»: Известный адвокат возмущена «щадящим» условным сроком для Навального 12:45, 10 Апр. Лидеру ФБК в 2017 году продлили испытательный срок до 2020 года. Адвокат Сталина Гуревич вновь призывает МВД обратить пристальное внимание на персону...

ТехнологииCS2: борьба за 200 тыс. долларов. Кто победит? 12:45, 10 Апр. В данной статье вы увидите обзор финалистов Elisa Masters Espoо 2023, а также общую информацию по турниру! Турнир Elisa Masters Espoo 2023 – это круп...

ТехнологииValve официально прекратила поддержку CS:GO 12:45, 10 Апр. Компания Valve объявила о прекращении поддержки легендарной игры Counter-Strike: Global Offensive с 1 января 2024 года.С начала нового года компания ...

ОсновноеНа Михайловском ГОКе приступил к работе новый 70-тонный гусеничный бульдозер 12:45, 10 Апр. На Михайловском ГОКе имени А.В. Варичева — входит в холдинг «Металлоинвест» — ввели в эксплуатацию тяжёлый гусеничный бульдозер. Его вес ...

СпортРезиновое покрытие для ледовых арен и открытых катков 12:45, 10 Апр. Небольшие ледовые арены могут обустраиваться не только в спортивных комплексах, но и на территории торгово-развлекательных центров. Здесь важно подоб...

СпортКак заказать Nike по доступной цене 12:45, 10 Апр. Nike – один из самых известных мировых брендов спортивной одежды и обуви. Эта американская компания была основана в 1964 году профессиональным бегуно...

ОсновноеОбщественники и блогеры обсудили перспективы платформы RuTube 12:45, 10 Апр. В студии Экспертного института социальных исследований на международной выставке-форуме «Россия» на ВДНХ состоялась стратегическая сессия с лидерами ...

ОсновноеПолитолог Скачко: Зеленский говорит о новом контрнаступлении ради денег от Запада 12:45, 10 Апр. ВСУ испытывают дефицит живой силы, но для очередной волны мобилизации нужны деньги. Поэтому Зеленский, вновь возвращаясь к теме контрнаступления, пыт...

ОсновноеЭксперт Сергей Горелов назвал пять важных для Брянска политических решений 12:45, 10 Апр. Брянск вошёл в ТОП-10 рейтинга Минстрой России по индексу качества городской среды. Участник «Экспертного клуба» из Брянской области Сергей Горелов п...

ОсновноеБрянский эксперт Сергей Горелов назвал спецоперацию ответом на нараставшую десятилетиями агрессию 12:45, 10 Апр. Десять лет назад, 7 апреля 2014 года, в Донецке был создан Республиканский народный совет. Он объявил о суверенитете Донецкой Народной Республики (ДН...

ТехнологииИнновации в плоском корпусе: ТВ Станция с Алисой. 12:45, 10 Апр. Яндекс объединил телевизор и умную колонку в мультифункциональном устройстве, которое понравится всем членам семьи. С ТВ Станцией можно не только смо...

ТехнологииКожные антисептики: незаменимые помощники в борьбе с бактериями и вирусами 12:45, 10 Апр. В наше время, когда гигиена стала особенно важной, кожные антисептики стали незаменимыми помощниками в поддержании здоровья. Эти специальные средства...

СпортФеерия «Реала» и «Ман Сити», ничья «Арсенала» и «Баварии», камбэк «Автомобилиста», 30-й гол и рекорд Овечкина, новый перл Загитовой и другие новости 12:45, 10 Апр. 1. «Реал Мадрид» и «Манчестер Сити» выдали концерт в Мадриде (3:3) в первом матче 1/4 финала Лиги чемпионов. «Горожане» дважды вели в счете. «Сливочн...

ШоубизСериал «Стас» 2021 на «ТНТ»: Описание серий, актёры и роли, дата выхода 12:45, 10 Апр. «Бытовуха» русского стендапера — основная идея сериала «Стас». Комик Старовойтов, пропавший с экранов, исполнил главную роль в ситкоме. Стас Старовой...

ШоубизКанделаки возглавила ТНТ вместо автора «Дома-2»: станет ли канал вторым Матч-ТВ 12:45, 10 Апр. Поклонники задумались, какие изменения ждут канал. Не столкнётся ли он с проблемами Матч ТВ, которым руководила Канделаки. Фото: pbs.twimg.com Тина К...

ОсновноеАвторский дизайн мягких панелей на стену: способы стяжки 12:45, 10 Апр. Использование мягких стеновых панелей – это один из самых актуальных трендов в современном интерьерном дизайне. Этот оптимальный способ создать уют и...

ОсновноеШкольники и учителя не хотят сокращения домашних заданий 12:45, 10 Апр. Правительству необходимо обеспечить разработку и реализацию мер по формированию "гармоничной, сбалансированной и результативной учебной и воспитатель...

ОсновноеТянет на природу: куда поехать на весеннюю прогулку недалеко от Петербурга 12:45, 10 Апр. Алексей Коткин, биолог, регулярно проводит экологические экскурсии по Петербургу и окресностям Алексей Коткин, биолог, регулярно проводит экологическ...

ОсновноеКурянам напоминают об опасности сомнительных торговых точек с шаурмой 12:45, 10 Апр. Популярная восточная закуска – шаурма, давно возглавляет хит-парад российского, и не только фаст-фуда. В каждом городе есть, то самое место, с ...

ОсновноеВ Курской области зарплата оказалась ниже средней по нашей стране на 23 процента 12:45, 10 Апр. Накануне один из популярных сервисов по поиску работы, проанализировал доход населения России. Так, в Курской области зарплата ниже средней по стране...

ОсновноеБрянские и белгородские баскетболисты участвуют в тренировочных играх 12:45, 10 Апр. Во Дворце единоборств имени Артема Осипенко в Брянске гостят белгородские ребята. Крупнейший спортивный объект стал домом и тренировочной площадкой д...

ОсновноеВ этом году в Брянске экзамены будут сдавать свыше семи тысяч выпускников 12:45, 10 Апр. В Брянске стартовала экзаменационная пора. Часть выпускников школ уже сдают ЕГЭ. Для них проходит досрочный экзаменационный этап. Всего же продемонст...

Основное«Ростелеком» в Твери презентовал цифровые сервисы для корпоративных клиентов 12:45, 10 Апр. «Ростелеком» организовал круглый стол для представителей бизнеса и госучреждений Верхневолжья. На мероприятии специалисты провайдера презентовали инт...

ОсновноеВ Тверской области газифицируют музеи 12:45, 10 Апр. 9 апреля под руководством Губернатора Игоря Рудени состоялось заседание Бюджетной комиссии Тверской области. В повестку вошли вопросы поддержки предп...

СпортМонте-Карло (ATP). Рублев играет с Попыриным, Хачанов – с Серундоло, Медведев встретится с Монфисом, Синнер – с Кордой, Зверев вышел в 3-й круг, Сафиуллин выбыл 12:45, 10 Апр. Даниил Медведев встретится с Гаэлем Монфисом. Накануне Роман Сафиуллин уступил Новаку Джоковичу. Сетка турнира здесь. Rolex Monte-Carlo Masters Монте...

Бизнес и ПромышленностьКак сейчас выглядит киллер, стрелявший во Владислава Листьева 12:45, 10 Апр. Читатели телеграм-канала ВЧК-ОГПУ получили уникальная возможность увидеть, как сейчас выглядят убийцы тележурналиста Владислава Листьева в 1995 году....

Бизнес и ПромышленностьНаместник клана Патрушевых на российском зерне 12:45, 10 Апр. На прошлой неделе Эдуард Зернин, председатель правления Союза экспортеров зерна дал интервью, в котором рассказал, что доля России на мировом рынке з...

Экология и ЗдоровьеBeOrganic — магазин аюрведических товаров: описание 12:45, 10 Апр. Интернет-магазин аюрведических товаров BeOrganic ставит перед собой задачу по продаже исключительно натуральной продукции. Она востребована у всех, к...

Экология и ЗдоровьеЛазерная эпиляция: удаление волос навсегда 12:45, 10 Апр. Избавление от нежелательных волос навсегда стало возможным при помощи применения современного метода – лазерной эпиляции. Безболезненный и безопасный...

ОсновноеОткрыта регистрация IV Всероссийского конкурса «Лидеры строительной отрасли» 12:45, 10 Апр. 7 марта на площадке информационного агентства «ТАСС» прошла пресс-конференция официального старта регистрации участников IV Всероссийского конкурса у...

ОсновноеВ Брянске экзамены будут сдавать свыше семи тысяч выпускников 12:45, 10 Апр. В Брянске началась экзаменационная пора. Часть выпускников школ уже проходят досрочный экзаменационный этап. Всего же к экзамену допущены 7 133 выпус...

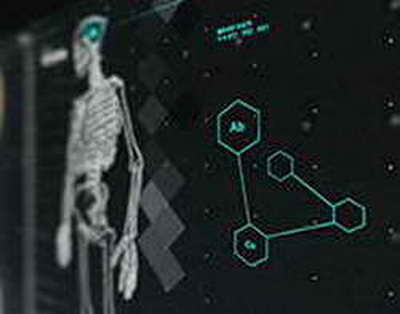

ТехнологииЧерепно-мозговые травмы меняют нейронные сети по всему мозгу 12:45, 10 Апр. Свежие научные открытия в области черепно-мозговых травм, сделанные американскими нейробиологами из Университета Тафтса в Массачусетсе, раскрывают но...

ОсновноеУмер спортивный комментатор Василий Уткин 12:44, 10 Апр. СМИ распространяют информацию о том, что умер спортивный комментатор Василий Уткин. Журналисту было всего 52 года.В последнее время Уткин сильно боле...

ОсновноеКонтртенор Люсьен Сур раскрыл секреты формирования уникального голоса вокалиста 12:44, 10 Апр. Люсьен, как начался Ваш творческий путь? Музыкой я занимаюсь с детства, наверное, лет с 6. Это все мама (улыбается). Она, увидев, мой талант сразу от...

ТехнологииMicrosoft заявляет, что Китай использует ИИ, чтобы посеять раскол в США 12:44, 10 Апр. Согласно последнему отчету центра угроз Microsoft, Китай наращивает использование контента, созданного искусственным интеллектом, и фейковых аккаунто...

ТехнологииБесчиповое волокно определяет взаимодействие с человеческим телом 12:44, 10 Апр. Бесчиповое волокно для беспроводной передачи изображения в цифру определяет взаимодействие с человеческим телом.Группа ученых-материаловедов и инжене...

Экономика и ФинансыПрогноз цен на золото: пара XAU/USD поднимается выше $2 350, инвесторы ожидают данных по CPI США 12:44, 10 Апр. Цена на золото торгуется на положительной территории в районе $2 355 на ранней европейской сессии в среду. Ожидание снижения ставки ФРС, рост напряже...

Экономика и ФинансыПрогноз цен на серебро: пара XAG/USD держится вблизи $28,10 на фоне эскалации геополитической напряженности 12:44, 10 Апр. Цена серебра выросла на ожиданиях снижения ставки ФРС в 2024 году. Низкодоходный актив, такой как серебро, дорожает на фоне снижения доходности казна...

Люди и Происшествия10 секретов выбора идеальной свадебной площадки: как выбрать место проведения свадьбы 12:44, 10 Апр. Во время объявления помолвки многие родственники и знакомые сразу задают вопрос: «Где будет свадьба». Вариантов бесчисленное множество, поэтому важно...

Люди и ПроисшествияПопулярные форматы для скачивания музыки и их особенности 12:44, 10 Апр. Возможность загружать и слушать музыку бесплатно в режиме онлайн стала очень популярной в последние годы, и существует множество аудиоформатов, котор...

Развлечения и ИнтернетMicrosoft заявляет, что Китай использует ИИ, чтобы посеять раскол в США 12:44, 10 Апр. Согласно последнему отчету центра угроз Microsoft, Китай наращивает использование контента, созданного искусственным интеллектом, и фейковых аккаунто...

Развлечения и ИнтернетПредставлена система сбора энергии для устройств IoT 12:44, 10 Апр. Энергия будущего: усовершенствованная система сбора энергии для устройств IoT. Исследователи разработали высокопроизводительный блок управления энерг...

Автомобили и рынки50 лет Volkswagen Golf 12:44, 10 Апр. Что такое «Гольф»? В масштабах отрасли — одна из самых удачных и популярных моделей. Ее именем назван целый класс! С точки зрения фан-фактора — акаде...

Автомобили и рынкиToyota полностью рассекретила внедорожник 4Runner нового поколения 12:44, 10 Апр. Со сменой поколения 4Runner преобразился, увеличился в размерах, перебрался на платформу TNGA-F, лишился двигателя V6 и обзавелся новыми комплектация...

Искусство, АртЕлизавета Арзамасова и Илья Авербух ждут второго ребёнка 12:44, 10 Апр. 29-летняя актриса Елизавета Арзамасова и 50-летний фигурист Илья Авербух снова станут родителями: супруги ждут второго общего ребёнка. О пополнении в...

Искусство, Арт14 вещей в горошек — самого стильного принта этой весны 12:44, 10 Апр. Горошек (polka dot) стал самым модным принтом этой весны, но не каждая готова примерить его. Марк Джейкобс говорил, что "для горошка не бывает неподх...

ТехнологииUnited Launch Alliance завершила эру Delta IV Heavy 9 апреля 12:44, 10 Апр. В историческом запуске 9 апреля компания United Launch Alliance (ULA) успешно запустила секретный спутник Национального разведывательного управления ...

ТехнологииApple Music: как сделать совместный плейлист 12:44, 10 Апр. Раньше все делились любимой новой музыкой с друзьями и семьей с помощью тщательно собранного физического носителя. Но для тех из нас, кто старше опре...

ТехнологииApple Mac: как заменить приложения по умолчанию 12:44, 10 Апр. Продукты Apple поставляются с программным обеспечением, предназначенным для совместной работы с операционной системой macOS. Например, Safari по умол...

Политические событияЛеонид Слуцкий предложил регламентировать работу микрофинансовых организаций 12:44, 10 Апр. Лидер ЛДПР Леонид Слуцкий поднял проблемный вопрос деятельности микрофинансовых организаций. Депутат заявил о необходимости изменить требования к их ...

Автомобили и рынкиВ ЛДПР предложили снять плату за проезд по трассе «Дон» для жителей Краснодара 12:44, 10 Апр. Лидер ЛДПР Леонид Слуцкий инициировал разрешение бесплатного проезда по трассе «Дон» для жителей Краснодара. Они поделились проблемой затратной местн...

ТехнологииРоссийские HSM модули: Новый этап в защите данных платежных систем 12:44, 10 Апр. В начале 2024 года российские банки столкнулись с важным решением: перейти на оборудование отечественного производства для защиты транзакций по пласт...

ТехнологииСколько в Турции стоит биткоин 12:44, 10 Апр. Биткоин, как криптовалюта, является объектом интереса для многих инвесторов и трейдеров во всем мире. Его стоимость может варьироваться в зависимости...

ТехнологииПочему аккаунт Google пишет «Ограничение по возрасту» и что делать? 12:44, 10 Апр. Некоторые пользователи при регистрации нового аккаунта Google получают уведомление об ограничении по возрасту — в результате создать учетную запись н...

ТехнологииПочему входящая скорость интернета низкая / меньше исходящей? 12:44, 10 Апр. По различным причинам входящая скорость мобильного интернета может оказаться ниже, чем исходящая. Расскажем, почему скорость загрузки меньше скорости...

ОсновноеОткрыта регистрация IV Всероссийского конкурса «Лидеры строительной отрасли» 12:44, 10 Апр. 7 марта на площадке информационного агентства «ТАСС» прошла пресс-конференция официального старта регистрации участников IV Всероссийского конкурса у...

ТехнологииТоп 10 - Лучшие проекторы для домашних кинотеатров в жилой комнате 12:43, 10 Апр. Под давлением быстрого снижения цен на телевизоры из обновленной версии обзора полностью исчезли бледные модели проекторов мощностью менее 300 Вт Гла...

ТехнологииТОП 5 - Лучшие LED/LASER проекторы для домашних кинотеатров 12:43, 10 Апр. LED/LASER проекторы пока так и не приблизились по ценам к ламповым моделям, а их уже вытесняют большие телевизоры, которые стремительно дешевеют Наст...

ТехнологииНеобычные часы SpaceTime Blade измеряют время в километрах 12:43, 10 Апр. Компания Urwerk зарабатывает тем, что выпускает необычные часы. В своей работе она придерживается максимально гибких подходов, а выдумка и оригинальн...

ТехнологииАлло, это кто? Как одно слово может обойтись дорого 12:43, 10 Апр. В современном мире, где технологии играют важную роль в нашей повседневной жизни, мошенники находят новые способы использовать эти инструменты для не...

Автомобили и рынкиКроссовер Dongfeng Haoji опробует новую платформу 12:43, 10 Апр. Среднеразмерный паркетник, сопоставимый со «вторым» Дунфэном 580, дебютирует в марте 2022 года и встанет на ступеньку выше Дунфэна AX7. Обе подвески ...

Автомобили и рынкиТест-драйв: Машем году, Драйву и Мазде CX-30 из Subaru XV и Peugeot 2008 12:43, 10 Апр. Обходимся без шипов. «Пыж» обут в Continental Viking Contact 7 комфортной размерности 215/60 R17. Для остальных выбрана Hakkapeliitta R3 SUV: 215/55 ...

ОсновноеВ Брянской области после атак погибли мальчик и женщина 12:43, 10 Апр. Сегодня Брянская область в очередной раз подверглась обстрелу. ВСУ постоянно атакуют регион, и такие новости уже стали привычными, как бы это страшно...

ОсновноеЭксперт Сергей Горелов дал комментарий к 10-летию конфликта в Донбассе 12:43, 10 Апр. В начале апреля 2014 года на востоке Украины начались события, которые положили начало вооруженному конфликту в Донбассе. Этой теме посвящено новое о...

СпортНХЛ. «Вашингтон» победил «Детройт», «Рейнджерс» проиграли «Айлендерс», «Филадельфия» пропустила 9 шайб от «Монреаля» 12:43, 10 Апр. «Айлендерс» обыграли «Рейнджерс» (4:2), «Тампа» разобралась с «Коламбусом» (5:2), «Филадельфия» была разгромлена «Монреалем» (3:9). НХЛ Регулярный че...

СпортФеерия «Реала» и «Ман Сити», ничья «Арсенала» и «Баварии», камбэк «Автомобилиста», 30-й гол и рекорд Овечкина, новый перл Загитовой и другие новости 12:43, 10 Апр. 1. «Реал Мадрид» и «Манчестер Сити» выдали концерт в Мадриде (3:3) в первом матче 1/4 финала Лиги чемпионов. «Горожане» дважды вели в счете. «Сливочн...

СпортМонте-Карло (ATP). Рублев играет с Попыриным, Хачанов – с Серундоло, Медведев встретится с Монфисом, Синнер – с Кордой, Зверев вышел в 3-й круг, Сафиуллин выбыл 12:43, 10 Апр. Даниил Медведев встретится с Гаэлем Монфисом. Накануне Роман Сафиуллин уступил Новаку Джоковичу. Сетка турнира здесь. Rolex Monte-Carlo Masters Монте...

ТехнологииПерспективы развития кибербезопасности в российском телекоммуникационном секторе 12:43, 10 Апр. Современный мир все больше становится цифровым, это происходит день ото дня, и телекоммуникационный сектор играет важную роль в этом процессе. Однако...

ТехнологииИспользование компьютерных программ для эффективного ведения социальных сетей 12:43, 10 Апр. В современном мире, где социальные сети стали неотделимой частью нашей жизни и ключевым инструментом для бизнеса, грамотное управление ими требует пр...

ОсновноеВ Самаре устанавливают желтые щиты с символикой дорожного нацпроекта: конструкции информируют горожан о ремонтных работах, запланированных в 2024 году 12:43, 10 Апр. В Самаре своевременно стартовали работы в рамках масштабного ремонта улично-дорожной сети по национальному проекту “Безопасные качественные дороги”. ...

ОсновноеТРИЗ на практике (Теория решения изобретательских задач) 12:43, 10 Апр. ТРИЗ (Теория решения изобретательских задач) – это система методов и приемов, разработанная Генрихом Альтшуллером в середине XX века, с целью с...

ТехнологииПодарите любимым оригинальные приветствия. Скажи миру: Привет! 12:43, 10 Апр. Жизнь в современном мире означает возможность услышать и произнести огромное количество приветствий. Люди здороваются с друзьями, родными, новыми зна...

ТехнологииСкачивание музыки на сайте mp3uk.net 12:43, 10 Апр. Самые свежие хиты музыки доступны для скачивания на нашем сайте, а также хиты классической музыки или популярные песни прошлых лет. Вы можете слушать...

Люди и ПроисшествияЭкс-министр Бишимбаев убивал свою красавицу-жену Салтанат Нукенову восемь часов 12:43, 10 Апр. В Казахстане в прямом эфире судят бывшего главу Министерства нацэкономики. Казахстан, затаив дыхание, следит за судебным процессом над бывшим министр...

Экономика и ФинансыСильный NFP способен углубить коррекцию в акциях, поддержать доллар 12:43, 10 Апр. Влияние на рынок:2Месячный отчёт по занятости обладает достаточным потенциалом, чтобы рынок определился с тенденцией на ближайшие недели. Но также ес...

Экономика и ФинансыЗолото временно игнорирует негатив 12:43, 10 Апр. Влияние на рынок:3Золото обновляет исторические максимумы почти ежедневно на протяжении последних двух недель, дойдя до $2365 на спот-рынке во вторни...

ШоубизДжеймс Майкл Тайлер: судьба Гантера из сериала «Друзья» 12:43, 10 Апр. Джеймс Майкл Тайлер – американский телевизионный актёр. Он начинал свою карьеру в Голливуде с низких должностей помощника монтажера и ассистента, одн...

ШоубизСергей Полунин - российский артист балета 12:43, 10 Апр. Сергей Полунин известен всему миру как гениальный танцовщик с бунтарским характером. У артиста яркая интересная жизнь и непростой творческий путь от ...

Экономика и ФинансыОбмен Kaspi Bank KZT на карту банка ТКС (Тинькофф) с максимальной выгодой 12:43, 10 Апр. Большинство пользователей, которым нужно провести обмен казахстанских тенге с карты Каспий Банка на рубли карты ТКС Банка, предпочитают пользоваться ...

Экономика и ФинансыКак выбрать правильный участок в Особой Экономической Зоне: Факторы для учета 12:43, 10 Апр. Компания, которая приобретает землю в особой экономической зоне, может получить преимущества. Большим преимуществом можно считать получение налоговых...

Автомобили и рынкиГазопоршневые установки 12:43, 10 Апр. Резервные газопоршневые установки обеспечивают надежное и эффективное функционирование систем газоснабжения в случае аварийных ситуаций или плановых ...

Автомобили и рынкиЭлектрический квадроцикл 12:43, 10 Апр. Электрические квадроциклы - это техника нового времени, которую выбирают из-за экологической безопасности, отсутствия выхлопных газов, относительной ...

ТехнологииMicrosoft заявляет, что Китай использует ИИ, чтобы посеять раскол в США 12:43, 10 Апр. Согласно последнему отчету центра угроз Microsoft, Китай наращивает использование контента, созданного искусственным интеллектом, и фейковых аккаунто...

ТехнологииПредставлена система сбора энергии для устройств IoT 12:43, 10 Апр. Энергия будущего: усовершенствованная система сбора энергии для устройств IoT. Исследователи разработали высокопроизводительный блок управления энерг...

ОсновноеРаботников госучреждений заставляют отписаться от Романа Алёхина 12:43, 10 Апр. Интересный приказ пришёл сверху для работников госучреждений и не только. Людей заставляют отписаться от общественного деятеля, социального технолога...

ТехнологииSamsung показала Galaxy S23 и S23+ с обновленным дизайном 12:43, 10 Апр. Вслед за Galaxy S23 Ultra сегодня показали и обновление базовых моделей Galaxy S. И хотя Samsung улучшила основные аппаратные и программные функции, ...

ТехнологииВ сети появились рендеры Sony Xperia 1 V 12:43, 10 Апр. Мы надеемся, что Xperia 1 V уже не за горами. По-прежнему существует определенная вероятность того, что телефон появится на выставке MWC в Барселоне ...

ТехнологииUnited Launch Alliance завершила эру Delta IV Heavy 9 апреля 12:43, 10 Апр. В историческом запуске 9 апреля компания United Launch Alliance (ULA) успешно запустила секретный спутник Национального разведывательного управления ...

ТехнологииБесчиповое волокно определяет взаимодействие с человеческим телом 12:42, 10 Апр. Бесчиповое волокно для беспроводной передачи изображения в цифру определяет взаимодействие с человеческим телом.Группа ученых-материаловедов и инжене...

ТехнологииПредставлена система сбора энергии для устройств IoT 12:42, 10 Апр. Энергия будущего: усовершенствованная система сбора энергии для устройств IoT. Исследователи разработали высокопроизводительный блок управления энерг...

ТехнологииДетский врач рассказала, как безопасно давать ребёнку опиоиды, если их ему прописали 12:42, 10 Апр. Допустим, вашему ребёнку только что сделали операцию. Даже спустя нескольких дней пребывания в больнице боль может оставаться всё ещё очень сильной. ...

ТехнологииЭксперты рассказали, как меняется мозг человека начиная с 30 лет 12:42, 10 Апр. Многие из нас хотят сохранить память и другие мыслительные навыки в старости примерно на том же уровне, что и в молодости. Однако с возрастом память ...

Бизнес и ПромышленностьЦены на нефть растут на фоне падения запасов нефти в долларах и США 12:42, 10 Апр. Нефть выросла в среду на фоне ослабления доллара, сокращения запасов сырой нефти в США и того, что Великобритания одобрила еще одну вакцину от корона...

Автомобили и рынкиШины для авто Altra Auto 12:42, 10 Апр. Тип установленных шин напрямую влияет на управляемость вашего авто и его способность к безопасному и эффективному передвижению в любое время года. Гр...

Автомобили и рынкиКалибры и другие инструменты от компании "Микрон" 12:42, 10 Апр. Калибры - это инструменты, предназначенные для контроля размеров и формы деталей, а также для определения наличия и характера дефектов на поверхностя...

ТехнологииТОП-10 крутых товаров с АлиЭкспресс, которые сложно найти в обычных магазинах 12:42, 10 Апр. Покупки на АлиЭкспресс актуальны и в 2024 году как минимум по двум причинам. Во-первых, на маркетплейсе цены зачастую ниже, а во-вторых — есть ...

ТехнологииКак запретить писать в Ватсап и заблокировать спам-сообщения 12:42, 10 Апр. Глава WhatsApp как-то отметил, что его мессенджер намного безопаснее Телеграма. Однако многие пользователи не поверили ему и лишь покрутили у виска. ...

ТехнологииMicrosoft прокачает рейтрейсинг на недорогих видеокартах 12:42, 10 Апр. Microsoft опубликовала патент, который представляет новый подход к сокращению объема памяти, требуемого для обработки графики с использованием технол...

ОсновноеУраган с востока рвет головы. Удар русских ракет поддал Киеву жару и огня 12:42, 10 Апр. Сегодняшний удар по военным объектам Украины был эффективным, точным и беспощадным. В Очакове уничтожена база боевиков ВСУ. В огне и под завалами пог...

ОсновноеОставьте в покое. Шеф Пентагона отчитал Киев за удары по российским НПЗ 12:42, 10 Апр. США опять переживают за российские НПЗ. На этот раз с осуждением ударов по нефтеперерабатывающим заводам выступил шеф Пентагона Ллойд Остин.Приказ из...

Экономика и ФинансыБесплатный курс по модели Po3 из 5 видео уроков 12:42, 10 Апр. Сегодня представляю вам Бесплатный курс по модели Po3 из 5 видео уроков. Её еще называют: Power of Three / Power of 3 / модель AMD / pattern AMD. Уже...

Экономика и ФинансыВидео курс «Волны Вульфа» — Бесплатно 12:42, 10 Апр. Выкладываю Видео курс «Волны Вульфа» абсолютно Бесплатно! Курс уже очень давно создан, его больше не продаем так же давно, паттерн Волны Ву...

ОсновноеКурянам напоминают об опасности сомнительных торговых точек с шаурмой 12:41, 10 Апр. Популярная восточная закуска – шаурма, давно возглавляет хит-парад российского, и не только фаст-фуда. В каждом городе есть, то самое место, с ...

ОсновноеВ Курской области зарплата оказалась ниже средней по нашей стране на 23 процента 12:41, 10 Апр. Накануне один из популярных сервисов по поиску работы, проанализировал доход населения России. Так, в Курской области зарплата ниже средней по стране...

Экономика и ФинансыЗачем банкам новые отделения и как мошенники обманывают их клиентов. Обзор Банки.ру 12:41, 10 Апр. 📰 Банки наращивают число отделений, рассказывают «Ведомости». Кто-то идет в города-миллионники, а кто-то — в небольшие, с населением от 30 000 челове...

Экономика и ФинансыОтыграть потери: аналитик предсказал, что произойдет с рублем 12:41, 10 Апр. Сегодня рубль может попытаться отыграть вчерашние потери, спрогнозировал главный аналитик финансового маркетплейса Банки.ру Богдан Зварич.Кнопка со с...

Бизнес и ПромышленностьКак сейчас выглядит киллер, стрелявший во Владислава Листьева 12:41, 10 Апр. Читатели телеграм-канала ВЧК-ОГПУ получили уникальная возможность увидеть, как сейчас выглядят убийцы тележурналиста Владислава Листьева в 1995 году....

Бизнес и ПромышленностьНаместник клана Патрушевых на российском зерне 12:41, 10 Апр. На прошлой неделе Эдуард Зернин, председатель правления Союза экспортеров зерна дал интервью, в котором рассказал, что доля России на мировом рынке з...

Закон и ВластьСтрашно жить: В Башкирии орудуют бандиты, выдающие себя за военных 12:41, 10 Апр. Известный в башкирском городе «подполковник» в очередной раз заставил горожан понервничать, рассказывая о своей любви к издевательствам. В Башкирии с...

Закон и ВластьТеневое истребление лесов оставило Сергея Шеверду без отпуска 12:41, 10 Апр. Задержанный министр лесного хозяйства Иркутской области может потянуть за собой и других видных «шишек» городской администрации вплоть до губернатора...

ОсновноеВ Брянске открыли завод по сбору грузовиков 12:41, 10 Апр. В Брянске открыли завод по сбору грузовиков из КНР Продавать продукцию будут под брендом BNM Мероприятие прошло 18 августа. На открытии присутствовал...

ОсновноеСборная команда Брянской области успешно выступила на Первенстве ЦФО по пауэрлифтингу 12:41, 10 Апр. В Туле завершилось Первенство Центрального федерального округа по пауэрлифтингу. Успешное выступление на соревновании продемонстрировала сборная спор...

ОсновноеОткрыта регистрация IV Всероссийского конкурса «Лидеры строительной отрасли» 12:41, 10 Апр. 7 марта на площадке информационного агентства «ТАСС» прошла пресс-конференция официального старта регистрации участников IV Всероссийского конкурса у...

ОсновноеВ Брянске экзамены будут сдавать свыше семи тысяч выпускников 12:41, 10 Апр. В Брянске началась экзаменационная пора. Часть выпускников школ уже проходят досрочный экзаменационный этап. Всего же к экзамену допущены 7 133 выпус...

ТехнологииЧерепно-мозговые травмы меняют нейронные сети по всему мозгу 12:41, 10 Апр. Свежие научные открытия в области черепно-мозговых травм, сделанные американскими нейробиологами из Университета Тафтса в Массачусетсе, раскрывают но...

Читаемое

Основное «Температура в комнатах 37 градусов»: жители ул. Ленина изнывают от жары и выпускают тепло на улицу

Закон и Власть Ремонт по ОСАГО: сервис требует доплату, законно ли это?

Люди и Происшествия «Почему он не в колонии?»: Известный адвокат возмущена «щадящим» условным сроком для Навального